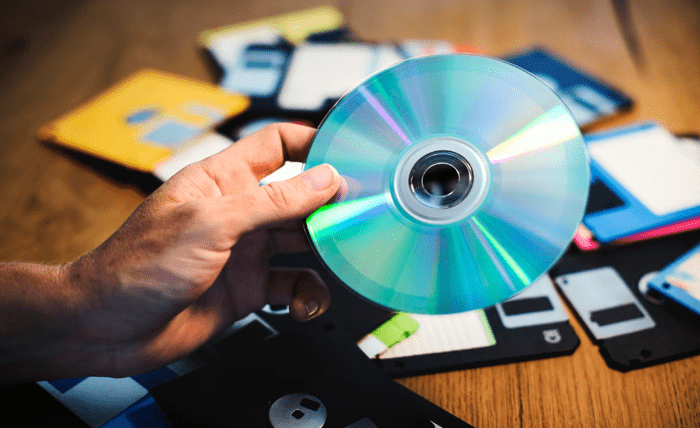

CD and DVD manufacturing remains a vital process for artists, filmmakers, and businesses seeking to distribute physical media in an increasingly digital world. Despite the rise of streaming platforms, physical discs offer a tangible connection to audiences, whether for music albums, software distribution, or archival purposes. This blog explores the intricate process of CD and DVD manufacturing, from mastering to packaging, and why it continues to hold value in 2025.

The Manufacturing Process

The journey of CD and DVD manufacturing begins with mastering, where the content—audio, video, or data—is prepared in a format suitable for replication. For CDs, this often involves creating a digital audio master, while DVDs require encoding video files into formats like MPEG-2. The master is then used to create a glass master, a high-precision template etched with microscopic pits representing the data. This glass master is the foundation for producing metal stampers, which are used to press the discs.

The replication process involves injecting molten polycarbonate into a mold, where the stamper imprints the data onto the disc. Once cooled, the disc is coated with a reflective layer, typically aluminum, and sealed with a protective lacquer. For DVDs, which can store more data, additional layers may be added for dual-layer discs, increasing capacity to 8.5 GB compared to a CD’s 700 MB. The precision required in this process ensures that each disc is an exact replica of the original master, maintaining quality across thousands or millions of units.

Quality Control and Customization

Quality control is paramount in CD and DVD manufacturing. Each batch undergoes rigorous testing to ensure readability and durability. Manufacturers check for physical defects, data integrity, and compatibility with various playback devices. Advanced facilities use automated systems to scan for errors, ensuring that every disc meets industry standards, such as those set by the International Organization for Standardization (ISO).

Customization is another key aspect. Discs can be screen-printed or offset-printed with vibrant artwork, logos, or tracklists, enhancing their aesthetic appeal. For example, limited-edition CDs for musicians often feature unique designs to attract collectors. Packaging options, such as jewel cases, digipaks, or eco-friendly cardboard sleeves, further personalize the product, catering to both practical and marketing needs.

Why Physical Media Persists

Despite digital dominance, CD and DVD manufacturing thrives in niche markets. Music enthusiasts value CDs for their uncompressed audio quality, which some argue surpasses streaming due to lossless formats like PCM. Similarly, DVDs remain popular for distributing high-quality video content, especially in regions with limited internet access or for archival purposes where physical media ensures longevity. Businesses also use CDs and DVDs for software distribution, training materials, and promotional content, as they offer a reliable, offline solution.

The collectible nature of physical media also drives demand. Fans of artists or filmmakers often prefer owning a tangible product